Something that has always struck me about petroleum geology is that our petroleum resources nearly always seem to be in the most remote parts of the planet. For the most part, gone are the days of the Esso exploration geologists that first discovered much of the petroleum in these remote areas. These days petroleum companies are spend massive amounts of energy looking for ways to further exploit the oil fields discovered by these pioneering geologists in some cases over 100 years ago. Thanks to John Hoopes (of Anadarko Petroleum) for this excellent explanation of the next big thing in petroleum exploration.

Disclaimer:

The following outline is meant to cover the fundamentals of Enhanced Oil Recovery (EOR) as accepted by most of the industry and does not reflect the methods used by Anadarko Petroleum exclusively. Details regarding exact depths, pressures and other company information have been omitted and the majority of the data presented is regarded as public knowledge.

Salt Creek Oil Field Background

|

|

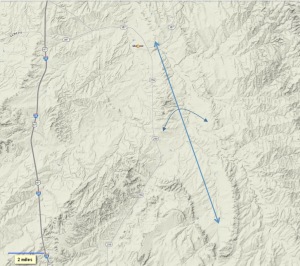

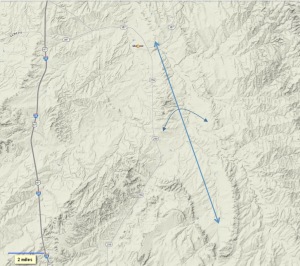

Salt Creek anticline as seen in surface topography –

Town of Midwest at top (2013 Google earth)

|

The Salt Creek oil field covers roughly 7 square miles in the north eastern Wyoming. It resides on the southwestern margin of the Powder River basin. The source rocks were principally deposited during the time of the Cretaceous seaway which bisected most of North America. Many oilfields in the Rocky Mountain region of the US and Canada are sourced from this time period and the presence of shallow to deep seas which eventually receded to the north. Laramide orogenic events (~40 Ma) created a series of westward verging anticlines along this portion of the state that are textbook examples of surface oil prospecting ‘made easy’. The field was discovered or had begun development as early as 1880. For many years the property changed ownership and struggled to see sustained or commercial development as the US was learning how to cope with westward transient expansion, steady labor and understand the complexities of oil and gas prospecting. With the discovery of several other profitable areas surrounding the city of Casper (south) and the addition of an oil refinery, Salt Creek, Teapot Dome, and other fields saw renewed interest. Initially, oil was hauled to Casper via wagon and later with small rail and pipelines.

|

|

Roughnecks in Salt Creek (1920’s) after having capped an uncontrolled oil well

|

Production from Salt Creek was constrained to the shallow Shannon sandstone and some porous and permeable pockets of the Niobrara shale. These intervals were so prolific that Salt Creek became the most productive field in Wyoming history. In 1915, the federal government noted the production and prolific oil reserves of the area that it set aside the Teapot Dome for the use of the Navy. Today, it stands as the sole field to have exceeded production of all others by cumulative barrels produced (approximately 692 barrels of oil by 2012).

Phases of Oil Field Development

Common practice for oil and gas development generally follows this sequence:

· Regional geologic modeling and study (basin type, modeling etc)

· Exploration(more focused surface and subsurface research and modeling-structure, source rock, reservoir rock) – Currently involves seismic imagery more than surface geology

· Test wells (either single or multiple wells drilled in an area to test for presence of hydocarbons, verify stratigraphy, porosity and permeability with a core or side wall plugs)

· Primary development (drilling an array of wells to produce productive areas, use of some water injection to maintain pressure)

· Secondary development (drilling some additional wells and beginning a water flood program [inject water to stimulate flow])

· Tertiary development (inject CO2 [or other gas] with water to stimulate flow, some additional wells drilled)

· Quaternary development (use of surfactants or other chemicals to reach zones not previously contacted by primary, secondary and tertiary methods)

Surprising to most, is the potential an oil field has since the primary phase of production usually yields 20-40% of the oil present. Secondary and Tertiary methods can be valuable assets in the right economic conditions where a single barrel is worth significantly more than it was a few or couple years earlier.

Stratigraphy and Strategy of EOR operations at Salt Creek

The salt Creek Oil Field life cycle is currently over 100 years old and is in the tertiary or EOR (Enhanced Oil Recovery) stage with some water flood processes taking place. Production of the field through the years has migrated to deeper units of the Frontier formation known as the Wall Creek 1 and Wall Creek 2. They represent a classic coarsening upward, forced regression sequences (falling stage) that extend across the eastern margin of Wyoming (left figure).

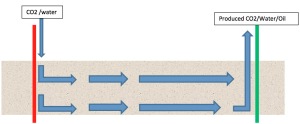

The majority of the EOR operation is designed to “sweep” or contact areas of the rock not affected or minimally affected by primary and secondary recovery efforts. In theory with steam or CO2 floods, the model is a injector-producer design. This method effectively pushes or displaces those fluids (oil) and gravitates towards a lower pressure created by the producing well (figure below).

This process can be altered further depending on well performance, fluid viscosities, and reservoir characteristics by alternating water and gas injection. This ‘pulse’ or “WAG”’ ing (water alternating gas) can disrupt preferred patterns of flow and allow for new areas of the reservoir to be flooded as the gas penetrates the rock matrix.

A key component to the EOR process is the pressure and temperature of the reservoir which allows for miscibility of the CO2. Without miscibility or injecting at the appropriate pressure, CO2 would remain in a gas phase and not permeate the rock in a uniform way with the residual waters that reside at depth. Therefore, not all reservoirs and conditions allow for EOR methods with CO2. Other chemical floods or injected media in “quaternary recovery” may be possible as their chemical makeups will allow for higher or lower pressures than those of CO2.

Another key component to EOR operations is the pattern design or array of wells that are utilized in the injection-production process. The “5-spot” pattern or a producer surrounded by a square of 4 injectors is the most common. Depending on isotropy, structure and depositional environment, the scale and orientation (and skewness) will need to be considered to flood and produce efficiently.

The future of oil and gas exploration, development and recovery will likely shift more and more to EOR methodology and doctrine. As these are not renewable resources, the desire of a company to extract the remaining resources in a cost effective way will be paramount and buffer the cost and risk of exploration and development elsewhere. A common adage heard among companies and other exploration geologists is: “all the easy oil has already been found”. Ironically there is a shift back to those resource plays and old oil fields where CO2 and other chemical floods are effective. These oil fields can become profitable again and become sources for economic stability for the surrounding region, be prepared for carbon sequestration and contribute to global resource supplies for several more decades.

The future of oil and gas exploration is shifting towards Enhanced Oil Recovery (EOR) methods to tap into remaining resources cost-effectively. As traditional reserves dwindle, there’s a renewed focus on older oil fields and resource plays where techniques like CO2 and chemical floods can make them profitable again. For investors seeking opportunities in this changing landscape, staying informed is crucial.

Oil Evex Ai offers insights and platforms to assist in making informed investment decisions in the evolving oil market, where resource optimization and sustainability are key.

|

|

A Work-Over rig is servicing a well on top of a mesa near the field. ‘Work over’ is a term used to generalize the operations that encompass any time an old (or new) wellbore needs to be re-entered for maintenance purposes. Considering the age of the Salt Creek field, a lot of old wellbores can be used but require this type of activity to ensure continual and safe operation.

|

|

|

A pump-jack in the Monell EOR field. 24 hours a day, 7 days a week and 365 days a year, pumps for injection and production are meticulously monitored for pressure and efficiency. Crews are assigned to portions of the field to care for the equipment at all times and ensure their ability to perform.

|

![]() This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.